Bitumen modified products are high-performance construction materials enhanced with bitumen, a viscous, black petroleum derivative. These products are specially designed to improve durability, weather resistance, and longevity in a wide range of applications. They include advanced solutions for waterproofing and roofing, road construction, protective coatings, and paving, ensuring superior performance under demanding conditions. The range includes Polymer Modified Bitumen, Crumb Rubber Modified Bitumen, Penetration Grade Modified Bitumen, Mastic Bitumen, and Blown Bitumen, offering versatile options for modern construction projects.

Mastic Bitumen is a type of asphalt that consists of graded mineral and asphaltic cement in a consistent solid or semi-solid form. It becomes fluid when heated and solidifies when cooled. It is commonly used in construction for floors, foundations, tanks, and acid-resistant brick lining to protect structures from corrosive attacks by weak acids, diluted alkalis, and salts. Additionally, it can be used as heavy-duty flooring in open mastic applications.

Blown bitumen, also known as oxidized bitumen, is produced by blowing air through heated bitumen. This process increases its softening point, stiffness, and viscosity. It is widely used in waterproofing, roofing, pavement applications, and in the manufacturing of paints, varnishes, and electrical products. Blown bitumen is available in various grades, from hard and brittle to soft and flexible, classified by softening point and penetration value.

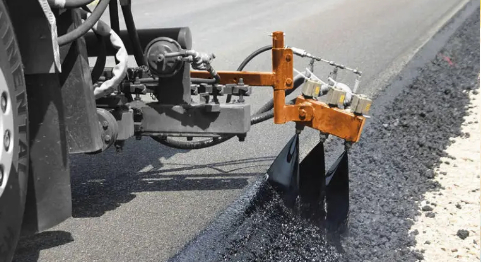

Polymer Modified Bitumen (PMB) is produced by modifying bitumen with polymer materials to enhance its performance. The polymer modification improves elasticity, durability, and resistance to deformation, making PMB suitable for road construction, waterproofing, roofing, and industrial applications. Common polymers used include SBS, SA, and EVA, tailored to meet specific performance requirements.

Crumb Rubber Modified Bitumen (CRMB) is an advanced asphalt product developed by modifying bitumen with chemically treated crumb rubber, natural asphalt, and Bismides chemicals. Natural asphalt contains high levels of asphaltene and nitrogen, which increase viscosity, raise the softening point, and reduce penetration. The rubber’s carbon content acts as an anti-oxidant, preventing aging and oxidation caused by prolonged exposure to sunlight.

Penetration Grade Bitumen is a widely used bitumen obtained from the refining of crude oil. It is classified based on its penetration value at 25°C, which indicates the hardness or softness of the material. Higher penetration values represent softer grades such as 160/220, while lower values represent harder grades like 85/100. This bitumen offers excellent waterproofing, strong adhesion, and resistance to deformation, making it suitable for diverse construction applications.